Asahi Kasei Introduces New XYRON™ mPPE Grades – Versatile Materials for Improved Efficiency of 5G Applications

New York, Düsseldorf and Tokyo – 21 September 2022 – To meet the increasing demand for materials that boost the efficiency of 5G applications, Asahi Kasei, diversified Japanese multinational company, is currently introducing new grades of its modified polyphenylene ether (mPPE) XYRON™ to the European and North American markets. The combination of PPE with other polymers such as polyphenylene sulfide (PPS) or polystyrene (PS) allows this family of high-performance compounds to feature a broad range of properties, exceeding those of conventional materials used for telecommunication applications.

5G networks are expected to offer maximum data transmission speeds about 10 times greater than those of 4G networks. Compared to their predecessors, 5G networks also use higher-frequency electromagnetic signals than previous network generations. However, this comes at a cost. As signal speeds increase, the strength of the signal becomes exponentially weaker, so high-frequency signals like 5G suffer much greater loss than lower-frequency signals like 4G, thus have greater difficulty in reaching their intended destinations. This poses challenges for network connectivity and can serve as an obstacle to ensuring reliable communication. For this reason, 5G networks require more base stations than previous generations, and 5G smartphone terminals must incorporate higher-performance radio systems to ensure reliability and satisfaction.

MID antennas for 5G-compliant smartphones

XYRON™ grades for MID (molded interconnected device) antennas feature low dielectric permittivity, low loss tangent and high hydrolysis resistance. Simulation results indicate that the use of these materials in MID antennas can improve total efficiency by as much as 1 dB compared to the polycarbonate (PC) materials conventionally used for this purpose. This enables operation at higher frequencies and more advanced device functionality, alleviating design space constraints to facilitate.

Antenna covers for 5G base stations

Antenna covers – the outermost layers of antenna assemblies – require lightweight, weather-resistant materials with low dielectric permittivity to improve electromagnetic-wave transmissivity. To date, antenna covers have typically been made from PC or similar materials, which hinders dielectric properties. Asahi Kasei is currently developing a XYRON™ grade with low dielectric permittivity, as well as an excellent hydrolysis and shock resistance that is available in all colors and is compliant with the UL94V-0 flame-retardance standard.

Asahi Kasei is also developing additional XYRON™ grades for various types of equipment covers, including grades with high weatherability, that resist color changes induced by prolonged light exposure.

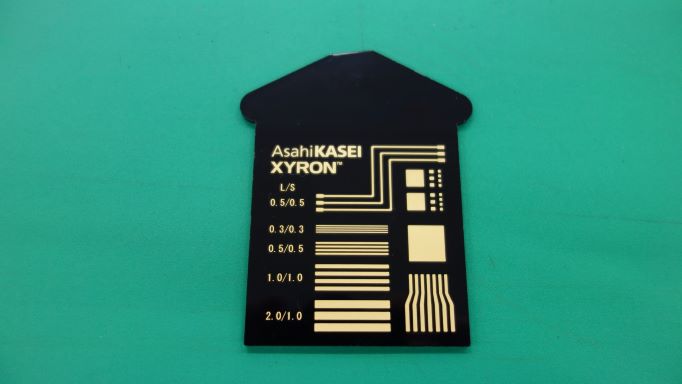

RF cavity filters for 5G base stations

Base stations commonly incorporate large numbers of metal or ceramic radio frequency (RF) filters that increase system weight, leading to a more complicated installation and operating losses. The greater density of base stations required for 5G networks makes these factors even more important and creates an urgent demand for lighter-weight components.

XYRONTM grades for RF filters – specifically designed for applications to RF cavity filters in 5G base stations – offer high heat resistance, good plating properties, and low linear-expansion coefficients comparable to those of metallic materials, facilitating the industry’s transition to resin-based RF filters.

Recycled PET/PPE alloys for 5G smartphone terminal chassis

Remaining committed to developing innovative materials for sustainable societies, Asahi Kasei is also introducing recycled PET/PPE alloys, which allow bonding to metals, for 5G smartphone terminal chassis as a new addition to the XYRON™ family, especially for the Chinese, US, Indian and Japanese markets. The new recycled grades combine PPE with various recycled resins to yield more sustainable manufacturing without sacrificing the high performance of these unique materials.

The recycled PET/PPE alloys use approximately 40% post-consumer recycled resins – recovered from PET bottles and other items – while retaining the good mechanical properties and lower dielectric properties than PBT and GF materials.

Asahi Kasei will exhibit its XYRON™ grades for 5G applications October 19-26 at the upcoming K 2022, “The World’s No. 1 Trade Show for Plastics and Rubber,” in Düsseldorf Germany (Hall 8a, Booth E23).

About the Asahi Kasei Corporation

The Asahi Kasei Group contributes to life and living for people around the world. Since its foundation in 1922 with ammonia and cellulose fiber businesses, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 46,000 employees around the world, the company contributes to a sustainable society by providing solutions to the world’s challenges through its three business sectors of Material, Homes, and Health Care. Its Materials sector, comprised of Environmental Solutions, Mobility & Industrial, and Life Innovation, includes a wide array of products from battery separators and biodegradable textiles to engineering plastics and sound solutions.

For more information, visit www.asahi-kasei.com.

Asahi Kasei is also dedicated to sustainability initiatives and is contributing to reaching a carbon neutral society by 2050. To learn more, visit https://www.asahi-kasei.com/sustainability/.

North America Media Inquiries

ATTN: Jonathan Todd

Asahi Kasei America, Inc.

info@ak-america.com

https://www.asahi-kasei.com

Europe Media Inquiries

ATTN: Sebastian Schmidt

Asahi Kasei Europe GmbH

AKEU-Info@asahi-kasei.eu

https://asahi-kasei.eu/