The Asahi Kasei TENAC™ Grades

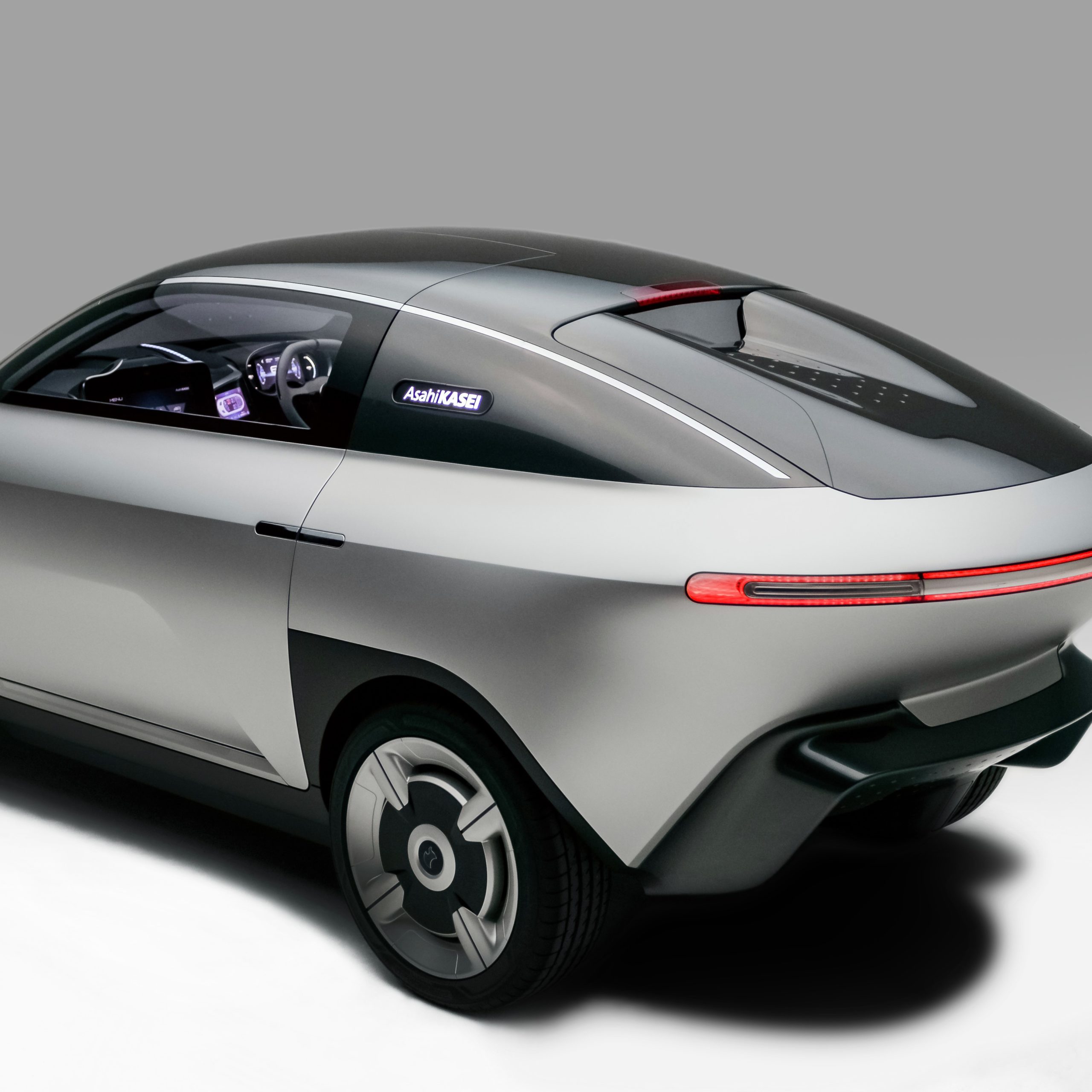

TENAC™ is the brand name of Asahi Kasei’s polyacetal (POM) product group. The TENAC™ grades are characterized by superior mechanical properties, above all, their dimensional stability, as well as excellent chemical resistance, ease of molding and extremely low emissions. They are used in a large number of applications – including especially interior fittings in the automotive sector.

Asahi Kasei is not only the sole POM manufacturer in the world to produces both Homo and Co-polymer, we successfully combined the positive properties of both qualities in one product, resulting in so the called “HC grades”, available in several viscosity grades.

Our broad TENAC™ product range also includes eco-friendly grades like the low emission TENAC™ Z series.

Table Of Content

Key Features of TENAC™ Homo-polymer

Due to its low-friction and high-wear properties combined with high strength and stiffness, TENAC™ homo-polymer is an ideal alternative for metal parts offering excellent dimensional stability. It combines high tensile strength, stiffness, creep and fatigue resistance, and significantly higher impact resistance making it possible to produce lighter parts in shorter production cycles contributing in reduction of production costs and environmental load.

Excellent Dimensional Stability

Excellent Creep and Fatigue Resistance

High Stiffness and Strength

Easy Processing Enabling Thinner and Lighter Parts

Low VOC-Emissions

Outstanding low-Friction Properties

Key Features of TENAC™-C Co-Polymer

In comparison with homo-polymers co-polymers provide a higher stability to heat and oxidative degradation. Therefore, they are often used in applications centered on mechanical components and critical parts demanding excellent chemical resistance.

Excellent Dimensional Stability

Outstanding Low-Friction Properties

Excellent Resistance to Creep, Fatigue and Chemicals

High Stiffness

Low VOC-Emissions

Low Water Absorption

Low-Emissions Grades

The in-cabin air quality is becoming increasingly important. With the increased use of plastics inside the car, the reduction of VOCs (volatile organic compounds) is becoming a key factor for an improved in-car air quality. TENAC™ can contribute to passenger safety and comfort trough improved cabin air quality by reducing VOC emissions (VOC value of < 2 ppm).

TENAC™

High viscosity: Z3010

Medium viscosity: Z4060

TENAC™-C

High viscosity: Z3510, Z3513

Medium viscosity: Z4520, Z4513, Z4563, ZH450, ZLV40

High flowability: ZH760, ZLD75

Weather-Resistant Grades

Developed to achieve high UV- and weathering resistance.

TENAC™

High viscosity 2013A – 3013A

Medium viscosity 4013A, 5013A

TENAC™-C

High viscosity: 3513

Medium viscosity: 4513, 4563

High flowability: 7513

Standard Grades

Both TENAC™ and TENAC™-C are available in high and medium viscosity as well as high flowability.

TENAC™

High viscosity 2010, 3010

Medium viscosity: 4010, 4060, 5010

High flowability: 7010

TENAC™-C

High viscosity: 3510

Medium viscosity: 4520, 5520

High flowability: 7520, 8520

High Durability Grades

Designed for highest performance in terms of creep resistance, compressive strength and molecular weight.

TENAC™

High viscosity: MG210

Medium viscosity: 4050

High-Cycle Grades

Feature very low viscosity and high flowability resulting in faster injection process and thus reducing the cycle time. Can also benefit processing applications with thin wall thickness.

TENAC™

Medium viscosity: 5050

High flowability: 7050, 7054

Super high flowability: 9054

TENAC™-C

High flowability: 7554

Anti-Scratch Grades

Reinforced grades to withstand scratch damage

TENAC™-C

Medium viscosity: HC460

High flowability: HC760

Reinforced Grades

(with glass fiber, mineral & carbon)

TENAC™

Medium viscosity: GA510, GA520

High flowability: GN705

TENAC™-C

Medium viscosity / electro-conductive: CF452, CF454

High flowability: GN755, MT754

High flowability / high lubricity: LD755

Metallic Grades

This type does not require additional painting and is mainly used in vehicle interiors due to its metallic appearance and low-emission properties.

TENAC™-C : ZM413

Impact Resistant (Silent) Grades

Contain elastomer for softer and reduced noise.

TENAC™ Medium viscosity: 4012

TENAC™-C Medium viscosity: SG454

Electro-Conductive Grades

Provide varying degrees of electro-conductivity and are especially suitable for applications where protection from static electricity and electromagnetic interference is required.

TENAC™-C

High flowability: EF-series (contains special carbon black)

Medium viscosity: TFC & CF-series

HC-Series

The newly developed Asahi Kasei TENAC™-C HC-grades combine the mechanical strength of a homo-polymer POM with the chemical resistance of a co-polymer POM. It results in a high performance co-polymer with improved physical properties and a high thermal stability and high mechanical strength.

– High mechanical strength

– Chemical resistance

TENAC™-C

-

- High viscosity: HC350

- Medium viscosity: HC450, HC55

- High flowability: HC750

Lubricated Grades

These grades convince with improved sliding and abrasion characteristics.

TENAC™

High viscosity: LT802

Medium viscosity: LT804, LT805, LT200, FS410, LP402, LA543, LM511

High flowability: LS701

TENAC™-C

High viscosity: LT350

Medium viscosity: LV450

High flowability: LZ750

High flowability/ reinforced: LD755